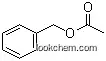

140-11-4Relevant articles and documents

Preparation of ammonium cerium phosphate via low-heating solid state reaction and its catalysis for benzyl acetate synthesis

Liao, Sen,Chen, Zhipeng,Liu, Gang,Tian, Xiaozhen,Wang, Tianshun,Wu, Wenwei

, p. 378 - 382 (2010)

Ammonium cerium phosphate was prepared with (NH4)3PO4?3H2O and Ce(SO4)2?4H2O as raw materials and PEG-400 as surfactant via a solid state reaction at low-heating temperature. The characterization result of XRD indicates that the molecular formula of the product was (NH4)2Ce(PO4)2?H2O. The synthesis of benzyl acetate was carried out with H2SO4/ammonium cerium phosphate as catalyst, and uniform experimental design as well as data mining technology was applied to the experiments, in which the effect of the reaction time, the molar ratio of acid to alcohol and the amount of catalyst on the conversion yield of acetic acid were studied. When benzalcohol was 0.10 mol, under the optimal reaction conditions, i.e. reaction time of 174 min, 2.02 of molar ratio of acid to alcohol and 0.5 g of catalyst, the esterification rate of acetic acid was 97.9%. The ammonium cerium phosphate had potential for industry application since it not only was feasible and simple in synthesis technics, but also had good catalysis activity for the synthesis of benzyl acetate.

Yoneda,Sakuma

, p. 1177 (1978)

Asymmetric syntheses of 8-oxabicyclo[3,2,1]octane and 11-oxatricyclo[5.3.1.0]undecane from glycals

Liao, Hongze,Leng, Wei-Lin,Le Mai Hoang, Kim,Yao, Hui,He, Jingxi,Voo, Amanda Ying Hui,Liu, Xue-Wei

, p. 6656 - 6661 (2017)

Herein, we describe an efficient method to prepare enantiomerically pure 8-oxabicyclo[3.2.1]octanes via gold(i)-catalyzed tandem 1,3-acyloxy migration/Ferrier rearrangement of glycal derived 1,6-enyne bearing propargylic carboxylates. The resultant compou

Inline Reaction Monitoring of Amine-Catalyzed Acetylation of Benzyl Alcohol Using a Microfluidic Stripline Nuclear Magnetic Resonance Setup

Oosthoek-De Vries, Anna Jo,Nieuwland, Pieter J.,Bart, Jacob,Koch, Kaspar,Janssen, Johannes W. G.,Van Bentum, P. Jan M.,Rutjes, Floris P. J. T.,Gardeniers, Han J. G. E.,Kentgens, Arno P. M.

, p. 5369 - 5380 (2019)

We present an in-depth study of the acetylation of benzyl alcohol in the presence of N,N-diisopropylethylamine (DIPEA) by nuclear magnetic resonance (NMR) monitoring of the reaction from 1.5 s to several minutes. We have adapted the NMR setup to be compatible to microreactor technology, scaling down the typical sample volume of commercial NMR probes (500 μL) to a microfluidic stripline setup with 150 nL detection volume. Inline spectra are obtained to monitor the kinetics and unravel the reaction mechanism of this industrially relevant reaction. The experiments are combined with conventional 2D NMR measurements to identify the reaction products. In addition, we replace DIPEA with triethylamine and pyridine to validate the reaction mechanism for different amine catalysts. In all three acetylation reactions, we find that the acetyl ammonium ion is a key intermediate. The formation of ketene is observed during the first minutes of the reaction when tertiary amines were present. The pyridine-catalyzed reaction proceeds via a different mechanism.

P-Cymenesulphonic acid: An organic acid synthesised from citrus waste

Clark, James H.,Fitzpatrick, Emma M.,MacQuarrie, Duncan J.,Pfaltzgraff, Lucie A.,Sherwood, James

, p. 144 - 149 (2012)

An organic acid, p-cymene-2-sulphonic acid, is synthesised from citrus waste and demonstrated to be comparable to p-toluenesulphonic acid in examples of acid catalysis. Firstly the essential oil found in citrus waste is extracted by either steam distillation or microwave irradiation. Oxidising the limonene in the citrus oil to p-cymene followed by sulphonation gives p-cymene-2-sulphonic acid.

Ultrasound assisted heteropoly acid catalyst SiW12/SiO 2 for synthesis of benzyl acetate

Chen, Xi,Wang, Jun,Han, Yue,Lu, Xiao-Ping,Han, Ping-Fang

, p. 623 - 627 (2013)

Under ultrasonic radiation, benzyl acetate is synthesized from benzyl alcohol and glacial acetic acid in presence of catalyst SiW12/ SiO2. The catalyst was prepared and characterized by IR, X-ray diffraction and SEM in the experiment. The XRD result indicates that heteropoly acid retains the Keggin-type structure. The kinetic parameters of reaction were, respectively measured at 90, 100 and 110 °C and the kinetic equation was built. Then, the effects of reaction temperature, the amount of catalyst, molar ratio of benzyl alcohol to glacial acetic acid and ultrasonic intensity on the esterification yield were discussed. The results showed that the optimum operating parameters for the present work when 10 kHz ultrasonic frequency and 1.0 W/cm2 ultrasonic intensity are as follows: reaction temperature: 110 °C, use amount of catalyst: 1.5 g, molar ratio of benzyl alcohol to glacial acetic acid: 1.5; reaction time: 75 min. Under such conditions, the esterification yield of the reaction reached above 95.3 %.

The Darbeau-White-Gibble reaction: An N-nitrosoamide-mediated Ritter-type reaction. Part I. A study of electronic, steric, and orbital effects in the nucleophile1a

Darbeau,Gibble,Pease,Bridges,Siso,Heurtin

, p. 1084 - 1090 (2001)

Benzyl cations were generated via thermal decomposition of N-benzyl-N-nitrosopivalamide in molten 4-R-substituted benzonitriles (R = NH2, Me2N, MeO, Me, H, F, and CF3). In each case, the benzyl cation was intercepted competitively by pivalate ion to yield benzyl pivalate and by the benzonitriles to yield the corresponding N-4-R-benzonitrilium ion. The latter onium ions reacted with pivalate ion to form benzimidic anhydrides which rearranged to yield N-4-R-benzoyl-N-pivaloylbenzylamines (i.e. unsymmetrical diacylamines). The yield of diacylamines (maximum ~10.6% for R = H) is smaller than from the corresponding reactions in acetonitrile and varied systematically with the nature and location of the R group on the aromatic nucleus. Both electron-releasing and electron-withdrawing groups at the para position effected a diminution of the yield of diacylamine; indeed for R = NH2, no diacylamine was formed. ortho Substitution of the aromatic nucleus resulted in significantly diminished yields of diacylamine, as did nucleophilic attack on the nitrilium ion by pivalate rather than acetate. Thus, both electronic and steric effects in nucleophilic attack on the nitrilium carbon were observed. The ratios of counterion-derived product to solvent-derived product for both the first-formed benzyl cation and the less reactive benzonitrilium ion are similar. This observation is interpreted in terms of the intermediacy of nitrogenous entity-separated ion-pairs in these deaminations.

Poly(ionic liquid)s based on imidazolium hydrogen carbonate monomer units as recyclable polymer-supported N-heterocyclic carbenes: Use in organocatalysis

Coupillaud, Paul,Pinaud, Julien,Guidolin, Nicolas,Vignolle, Joan,Fevre, Mareva,Veaudecrenne, Ellen,Mecerreyes, David,Taton, Daniel

, p. 4530 - 4540 (2013)

Synthesis of novel poly(ionic liquid)s, namely, poly(1-vinyl-3- alkylimidazolium hydrogen carbonate)s, denoted as poly([NHC(H)][HCO 3])s or PVRImHCO3, where R is an alkyl group (R = ethyl, butyl, phenylethyl, dodecyl), is described. Two distinct synthetic routes were explored. The first method is based on the free-radical polymerization (FRP) of 1-vinyl-3-alkylimidazolium monomers featuring a hydrogen carbonate counter anion (HCO3-), denoted as VRImHCO3. The latter monomers were readily synthesized by alkylation of 1-vinylimidazole (VIm), followed by direct anion exchange of 1-vinyl-3-alkylimidazolium bromide monomers (VRImBr), using potassium hydrogen carbonate (KHCO3) in methanol at room temperature. Alternatively, the same anion exchange method could be applied onto FRP-derived poly(1-vinyl-3-alkylimidazolium bromide) precursors (PVRImBr). All PVRImHCO3 salts proved air stable and could be manipulated without any particular precautions. They could serve as polymer-supported precatalysts to generate polymer-supported N-heterocyclic carbenes, referred to as poly(NHC)s, formally by a loss of "H2CO3" (H2O +CO2) in solution. This was demonstrated through selected organocatalyzed reactions of molecular chemistry, known as being efficiently mediated by molecular NHC catalysts, including benzoin condensation, transesterification and cyanosilylation of aldehyde. Of particular interest, recycling of the polymer-supported precatalysts was possible by re-carboxylation of in situ generated poly(NHC)s. Organocatalyzed reactions could be performed with excellent yields, even after five catalytic cycles.

ACETYLATION BY KETENE OF ALCOHOLS SUPPORTED ON SOLID ADSORBENTS

Chihara, Teiji,Takagi, Yuzuru,Teratani, Shousuke,Ogawa, Haruo

, p. 1451 - 1452 (1982)

Primary, secondary, and tertiary alcohols supported on solid adsorbents such as alumina, silica gel, celite, magnesium oxide, zinc oxide, titanium oxide, and charcoal were acetylated by ketene in good yields.

Synthesis and applications of quaternized highly branched polyacrylamide as a novel multi-site polymeric phase transfer catalyst

Mahdavi, Hossein,Amirsadeghi, Mehdi

, p. 791 - 797 (2013)

In current study, quaternized highly branched polyacrylamide (HBAA) was synthesized and used as an efficient multi-site polymeric phase transfer catalyst in nucleophilic substitution reactions and also in synthesis of α, β-unsaturated nitriles from reaction of acetonitrile and carbonyl compounds. The quaternized HBAA was synthesized via two steps. First, HBAA was synthesized via self-condensing vinyl polymerization of acrylamide at appropriate molar ratio of monomer to diperiodatocuprate(III). In the second step, 3-acrylamidopropyl trimethylammonium iodide was polymerized on peripheral area of the HBAA in the presence of diperiodatocuprate(III) solution again. The thermal behavior of HBAA and that of the quaternized HBAA were studied by DSC and TGA analysis. This phase transfer catalyst was easily recovered after reaction and reused several times without any loss of activity.

Glycerol-glycerol triacetate mixtures as green reaction mediums

Wolfson,Dlugy,Mordechaiev,Sliman,Tavor

, p. 240 - 242 (2014)

Three representative organic reactions were performed in various glycerol-triacetin mixtures to tune the polarity of the reaction mixture and thus to increase both the solubility of reactants and the product yields. In all reactions, it was found that reaction performance was affected by the glycerol to triacetin ratio as the solubility of the substrates in the solvent determined product yield. Thereby, employing optimal glycerol to triacetin ratio will result in maximum product yield.

Encapsulated N-heterocyclic carbenes in silicones without reactivity modification

Bonnette, Fabien,Kato, Tsuyoshi,Destarac, Mathias,Mignani, Gerard,Cossio, Fernando P.,Baceiredo, Antoine

, p. 8632 - 8635 (2007)

(Chemical Equation Presented) Let them off the leash! Silicone protecting media allow the manipulation and storage of air- and moisture-sensitive N-heterocyclic carbenes (NHCs). Calculations show that a weak carbene-Lewis acid interaction minimizes decomposition of NHCs but does not inhibit NHC reactivity.

Poly(ethylene glycols) as Soluble, Recoverable, Phase-Transfer Catalysts

Harris, J. Milton,Hundley, Nedra H.,Shannon, Thomas G.,Struck, Evelyn C.

, p. 4789 - 4791 (1982)

-

Key properties promoting high activity and stability of supported PdSb/TiO2 catalysts in the acetoxylation of toluene to benzyl acetate

Gatla,Madaan,Radnik,Kalevaru,Pohl,Lücke,Martin,Brückner

, p. 104 - 112 (2011)

The influence of thermal pretreatment in air, helium and 10% H 2/He on the catalytic performance of a supported 9% Pd, 12% Sb/TiO2 catalyst in the gas phase acetoxylation of toluene has been studied by integrated evaluation of catalytic tests and catalyst characterization using mainly XRD, TEM and XPS. A pretreatment temperature of 600 °C is beneficial for shortening the activation period, while the atmosphere during thermal pretreatment influences the long-term stability. Highest catalytic performance with a good long-term stability was reached with pretreatment in He, which creates Sb-containing Pd particles, on which a mixed Pd0/PdO surface is formed during time on stream. Sb stabilizes oxidized Pd species and leads to more stable catalysts in contrast to air-calcined samples. The catalyst pretreated in H2/He was completely inactive, due to the formation of a stable Pd8Sb3 alloy.

The Impact of Reaction Pressure on the Catalytic Performance of the Pd-Sb/TiO2 Catalyst in the Acetoxylation of Toluene into Benzyl Acetate

Madaan, Neetika,Gatla, Suresh,Kalevaru, Venkata Narayana,Radnik, Joerg,Pohl, Marga-Martina,Luecke, Bernhard,Brueckner, Angelika,Martin, Andreas

, p. 185 - 191 (2013)

The acetoxylation of toluene in the presence of acetic acid and oxygen was performed over a Pd-Sb/TiO2 catalyst at 210°C and at various reaction pressures (1-10bar). A remarkable improvement in the catalytic performance and a significant shortening of the induction period were found with an increase in pressure. At a pressure of 6bar, the highest toluene conversion of 75% and 100% selectivity for benzyl acetate were observed. This result could be due to both the restructuring of the catalyst surface and to the formation of active Pd-Sb particles of desired size, composition, and shape during the course of the induction period. Samples of the most-active and spent catalysts were studied by ex situ and insitu XRD, XPS, and TEM.

CARBON SILICON BOND CLEAVAGE IN THE OXIDATION OF BENZYLIC SILANES BY CERIUM(IV) AMMONIUM NITRATE

Baciocchi, Enrico,Del Giacco, Tiziana,Rol, Cesare,Sebastiani, Giovanni Vittorio

, p. 3573 - 3576 (1989)

Benzyltrimethylsilanes react with cerium(IV) ammonium nitrate in AcOH to give products of C-Si cleavage (benzyl nitrate and acetate), under very mild conditions and in quantitative yields.The reaction rate is very sensitive to the nature of the ring substituents (ρ= -5.4), which clearly suggests the operation of one electron transfer mechanism.

Straightforward synthesis of N-protected benzylic amines by carbamoalkylation of aromatic compounds

Bensel, Nicolas,Pevere, Virginie,Desmurs, Jean Roger,Wagner, Alain,Mioskowski, Charles

, p. 879 - 882 (1999)

A wide range of alkoxycarbonyl protected benzylic amines have been synthesized in a three component reaction involving a carbamate an aldehyde and an aromatic substrate. This reaction proceeds through electrophilic substitution of the aromatic compound by a N-carbamoyl iminium which is generated in situ by condensation of the carbamate with the aldehyde.

New strategies for the synthesis of lactones using peroxymonosulphate salts, ionic liquids and microwave or ultrasound irradiation

Matuszek, Karolina,Zawadzki, Przemyslaw,Czardybon, Wojciech,Chrobok, Anna

, p. 237 - 241 (2014)

A new method for the rapid synthesis of lactones via the one-pot oxidation of alcohols with potassium peroxymonosulphate in an ionic liquid was developed. The use of microwave or ultrasonic irradiation increased the reaction rates significantly. Additionally, new peroxymonosulphate ionic liquids were synthesised and used as effective oxidants in the synthesis of lactones. The Royal Society of Chemistry and the Centre National de la Recherche Scientifique 2014.

Catalytic activity comparison of Zr-SBA-15 immobilized by a Br?nsted-Lewis acidic ionic liquid in different esterifications

Dai, Liming,Zhao, Qian,Fang, Minglan,Liu, Ruifeng,Dong, Mingfeng,Jiang, Tingshun

, p. 32427 - 32435 (2017)

Zirconium-incorporated SBA-15 mesoporous molecular sieves (Zr-SBA-15) with different Si/Zr molar ratios were one-pot synthesized and characterized by XRD, TEM and N2 physical adsorption. The Br?nsted-Lewis acidic ionic liquid 1-(3-sulfonic acid)-propy l-3-methylimidazole chlorozincinate ([mim-ps]Cl-ZnCl2) was prepared by a hydrothermal process and its acidity was measured by FT-IR spectroscopy using acetonitrile and pyridine as probes. The Zr-SBA-15 catalyst immobilized by [mim-ps]Cl-ZnCl2 (Zr-SBA-15/[mim-ps]Cl-ZnCl2) was prepared by a wet impregnation method and characterized by XRD, BET, FT-IR spectroscopy, TEM, XPS and TG. In particular, the catalytic activities of Zr-SBA-15 and Zr-SBA-15/[mim-ps]Cl-ZnCl2 in the esterification of acetic acid were evaluated with n-butyl alcohol (n-BuOH), benzyl alcohol (BnOH) and cyclohexanol (Naxol). The results show that Zr-SBA-15/[mim-ps]Cl-ZnCl2 exhibited enhanced catalytic properties compared to Zr-SBA-15. Under optimal conditions, the acetic acid conversion over Zr-SBA-15/[mim-ps]Cl-ZnCl2 reached 89.7, 93.6, and 84.9% for n-BuOH, BnOH and Naxol, respectively. After 5 cycles, the acetic acid conversion decreased slightly. Zr-SBA-15/[mim-ps]Cl-ZnCl2 was found to be an outstanding catalyst for esterification.

Synthesis and characterization of Cp2Zr(C9H9O)2: A new zirconocene derivative catalyzed acetylation of 2-naphtol and benzyl alcohol

Tarassoli, Abbas,Mohmedi-Kartalaee, Hadi

, p. 513 - 517 (2015)

The new zirconocene compound, Cp2Zr(C9H9O)2, was successfully prepared from the reaction of zirconocene dichloride with 1-indanol in 1:2 molar ratio in dry chloroform at the presence of triethylamine (Et3/

Catalytic upgrading of carboxylic acids as bio-oil models over hierarchical ZSM-5 obtained: Via an organosilane approach

Rodponthukwaji, Kamonlatth,Wattanakit, Chularat,Yutthalekha, Thittaya,Assavapanumat, Sunpet,Warakulwit, Chompunuch,Wannapakdee, Wannaruedee,Limtrakul, Jumras

, p. 35581 - 35589 (2017)

Biomass is an interesting renewable energy resource as it is widespread in nature and low cost. The development of bio-oil derived from biomass as a fuel is still a scientific and industrial challenge. In this context, we demonstrate the synthetic method of bio-oil upgrading catalysts based on hierarchical zeolites and open up interesting perspectives for bio-oil upgrading processes. The hierarchical ZSM-5 zeolite has been successfully prepared via a direct hydrothermal synthesis with the aid of a commercial organosilane surfactant (TPOAC). The influences of TPOAC content and Si/Al ratio on hierarchical structures were also systematically studied. To illustrate their catalytic performances, an esterification reaction of various organic acids such as (acetic acid and levulinic acid) and alcohols was performed as the model reaction representing the bio-oil upgrading application. The synergic effect of acidity and the hierarchical structure of catalysts can greatly enhance the catalytic performance in terms of activity, product yield, coke formation, and reusability of the catalysts. For example, they can convert almost 100% of reactant in 8 h in the esterification of acetic acid and alcohols, whereas the conventional zeolite reveals significantly lower activity (20%). Interestingly, the hierarchical zeolite can also greatly improve the catalytic activity of the esterification of levulinic acid and ethanol to produce ethyl levulinate that can be used as a diesel miscible biofuel (DMB). In addition, the efficiency of hierarchical catalysts obtained by different synthesis methods is also discussed. This first example demonstrates that the hierarchical zeolite obtained via a direct synthesis approach can benefit bio-oil upgrading applications via the esterification of various carboxylic acids.

-

Paukstelis,J.V.,Kim,M.

, p. 1503 - 1507 (1974)

-

Structural characterization and substrate specificity of VpAAT1 protein related to ester biosynthesis in mountain papaya fruit

Morales-Quintana, Luis,Fuentes, Lida,Gaete-Eastman, Carlos,Herrera, Raúl,Moya-León, María Alejandra

, p. 635 - 642 (2011)

The aroma in fruits is an important attribute of quality that influences consumer's acceptance. This attribute is a complex character determined by a set of low molecular weight volatile compounds. In mountain papaya fruit (Vasconcellea pubescens) the aroma is determined mainly by esters, which are produced through an esterification reaction catalyzed by the enzyme alcohol acyltransferase (AAT) that utilizes alcohols and acyl-CoAs as substrates. In order to understand the molecular mechanism involved in the production of esters in this fruit, an AAT gene which has been previously cloned and characterized from mountain papaya (VpAAT1) was expressed in yeasts, and the highest enzyme activity of the recombinant protein was obtained when the enzyme was tested for its ability to produce benzyl acetate. On the other hand, to gain insight the mechanism of action at the molecular level, a structural model for VpAAT1 protein was built by comparative modelling methodology, which was validated and refined by molecular dynamics simulation. The VpAAT1 structure consists of two domains connected by a large crossover loop, with a solvent channel in the center of the structure formed between the two domains. Residues H166 and D170, important for catalytic action, displayed their side chains towards the central cavity of the channel allowing their interaction with the substrates. The conformational interaction between the protein and several ligands was explored by molecular docking simulations, and the predictions obtained were tested through kinetic analysis. Kinetic results showed that the lowest KM values were obtained for acetyl-CoA and benzyl alcohol. In addition, the most favorable predicted substrate orientation was observed for benzyl alcohol and acetyl CoA, showing a perfect coincidence between kinetic studies and molecular docking analysis.

Noncross-linked polystyrene nanoencapsulation of ferric chloride: A novel and reusable heterogeneous macromolecular Lewis acid catalyst toward selective acetylation of alcohols, phenols, amines, and thiols

Alinejad, Sara,Donyapeyma, Ghazaleh,Rahmatpour, Ali

, (2022/01/24)

Ferric chloride has been successfully nanoencapsulated for the first time on a non-cross-linked polystyrene matrix as the shell material via the coacervation technique. The resulting polystyrene nanoencapsulated ferric chloride was used as a novel and rec

ZWITTERIONIC CATALYSTS FOR (TRANS)ESTERIFICATION: APPLICATION IN FLUOROINDOLE-DERIVATIVES AND BIODIESEL SYNTHESIS

-

Paragraph 0012; 0013; 0028, (2021/01/29)

An amide/iminium zwitterion catalyst has a catalyst pocket size that promotes transesterification and dehydrative esterification. The amide/iminium zwitterions are easily prepared by reacting aziridines with aminopyridines. The reaction can be applied a wide variety of esterification processes including the large-scale synthesis of biodiesel. The amide/iminium zwitterions allow the avoidance of strongly basic or acidic condition and avoidance of metal contamination in the products. Reactions are carried out at ambient or only modestly elevated temperatures. The amide/iminium zwitterion catalyst is easily recycled and reactions proceed in high to quantitative yields.

Discovery and Design of Family VIII Carboxylesterases as Highly Efficient Acyltransferases

Müller, Henrik,Godehard, Simon P.,Palm, Gottfried J.,Berndt, Leona,Badenhorst, Christoffel P. S.,Becker, Ann-Kristin,Lammers, Michael,Bornscheuer, Uwe T.

supporting information, p. 2013 - 2017 (2020/11/30)

Promiscuous acyltransferase activity is the ability of certain hydrolases to preferentially catalyze acyl transfer over hydrolysis, even in bulk water. However, poor enantioselectivity, low transfer efficiency, significant product hydrolysis, and limited substrate scope represent considerable drawbacks for their application. By activity-based screening of several hydrolases, we identified the family VIII carboxylesterase, EstCE1, as an unprecedentedly efficient acyltransferase. EstCE1 catalyzes the irreversible amidation and carbamoylation of amines in water, which enabled the synthesis of the drug moclobemide from methyl 4-chlorobenzoate and 4-(2-aminoethyl)morpholine (ca. 20 % conversion). We solved the crystal structure of EstCE1 and detailed structure–function analysis revealed a three-amino acid motif important for promiscuous acyltransferase activity. Introducing this motif into an esterase without acetyltransferase activity transformed a “hydrolase” into an “acyltransferase”.

Xi:Irritant;

Xi:Irritant;