5343-92-0Relevant articles and documents

Baeyer-villiger oxidation of acyl carrier protein-tethered thioester to acyl carrier protein-linked thiocarbonate catalyzed by a monooxygenase domain in FR901464 biosynthesis

Tang, Man-Cheng,He, Hai-Yan,Zhang, Feng,Tang, Gong-Li

, p. 444 - 447 (2013)

Baeyer-Villiger monooxygenases (BVMOs), generally catalyzing the transformation of carbonylic compounds into the corresponding esters or lactones known as Baeyer-Villiger oxidation in organic chemistry, are widely distributed among microorganisms and have stimulated great interest as biocatalysts for organic synthesis. The physiological roles of this type of MOs are usually classified as degradation of organic compounds involved in primary metabolism. Recently, increasing numbers of BVMOs have been found to be involved in the biosynthesis of secondary metabolites, especially for postmodification; however, to date, none of them has been reported functionally as a tailoring domain within polyketide synthase (PKS) acting on carrier protein-tethered substrates. FR901464, an antitumor natural product that targets spliceosome and inhibits both splicing and nuclear retention of pre-mRNA, was elucidated to be biosynthesized by a hybrid acyltransferase-less PKS/nonribosomal peptide synthetase (NRPS) system. Within the hybrid system, an unprecedented domain that was proposed to mediate the chain release process was located in the termination module. In this paper, we report the in vitro biochemical characterization of this domain to be a BVMO tailoring domain that catalyzes the BV oxidation of an acyl carrier protein (ACP)-tethered thioester to an ACP-linked thiocarbonate, which represents the first example of BVMOs operating in cis within the PKS and NRPS biosynthetic paradigm.

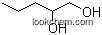

Unravelling the one-pot conversion of biomass-derived furfural and levulinic acid to 1,4-pentanediol catalysed by supported RANEY Ni-Sn alloy catalysts

Ansyah, Fathur Razi,Astuti, Maria Dewi,Hara, Takayoshi,Husain, Sadang,Mustikasari, Kamilia,Rodiansono,Shimazu, Shogo

, p. 241 - 250 (2022/01/19)

Bimetallic Ni-Sn alloys have been recognised as promising catalysts for the transformation of furanic compounds and their derivatives into valuable chemicals. Herein, we report the utilisation of a supported bimetallic RANEY nickel-tin alloy supported on aluminium hydroxide (RNi-Sn(x)/AlOH; x is Ni/Sn molar ratio) catalysts for the one-pot conversion of biomass-derived furfural and levulinic acid to 1,4-pentanediol (1,4-PeD). The as prepared RNi-Sn(1.4)/AlOH catalyst exhibited the highest yield of 1,4-PeD (78%). The reduction of RNi-Sn(x)/AlOH with H2 at 673-873 K for 1.5 h resulted in the formation of Ni-Sn alloy phases (e.g., Ni3Sn and Ni3Sn2) and caused the transformation of aluminium hydroxide (AlOH) to amorphous alumina (AA). The RNi-Sn(1.4)/AA 673 K/H2 catalyst contained a Ni3Sn2 alloy as the major phase, which exhibited the best yield of 1,4-PeD from furfural (87%) at 433 K, H2 3.0 MPa for 12 h and from levulinic acid (up to 90%) at 503 K, H2 4.0 MPa, for 12 h. Supported RANEY Ni-Sn(1.5)/AC and three types of supported Ni-Sn(1.5) alloy (e.g., Ni-Sn(1.5)/AC, Ni-Sn(1.5)/c-AlOH, and Ni-Sn(1.5)/γ-Al2O3) catalysts afforded high yields of 1,4-PeD (65-87%) both from furfural and levulinic acid under the optimised reaction conditions.

Highly selective 1-pentene epoxidation over Ti-MWW with modified microenvironment of Ti active sites

Jiang, Jingang,Tian, Wenwen,Wang, Bowen,Wu, Peng,Xu, Hao,Yin, Jianyong,Yin, Jinpeng

, p. 6050 - 6064 (2020/09/23)

A titanosilicate/H2O2catalytic system was applied to process the liquid-phase selective epoxidation of 1-pentene to 1,2-epoxypentane (EP). The effects of titanosilicate topology (MWW, MFI, MSE, MEL, MOR, and *BEA), solvent, H2O/H2O2ratio, catalyst amount, reaction temperature, pressure, and time on the EP production were investigated systematically. The Ti-MWW/H2O2/acetonitrile system exhibited the highest 1-pentene conversion of 72.9% together with high EP selectivity of 99.9% and H2O2utilization efficiency of 91.5%. Moreover, it was proved that the Ti active sites located inside the intralayer 10-membered ring sinusoidal channels catalyzed the epoxidation process primarily owing to their supplying more steric fitness for 1-pentene molecules. A piperidine (PI)-assisted structural rearrangement of Ti-MWW was performed to further enhance the catalytic activity, almost doubling the turnover number value. The evolution of the microenvironment of Ti active sites in this structural rearrangement process was carefully investigated, revealing the coordination of N atoms in PI molecules to the Ti atoms. More importantly, we identified that the hexa-coordinated Ti sites with the PI molecules as ligand could significantly accelerate H2O2activation, the effect of which far exceeded the inhibition effect caused by the electronegativity increase of Ti active sites.