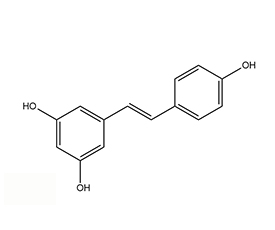

CAS:501-36-0Purity:20%,50%,98%

Quality Control

Stable Supply

Factory Direct Supply

Complete Supply Chain

1. Natural antioxidants: prevent cardiovascular disease, inhibit platelet aggregation, anti-thrombosis, reduce blood lipids and the incidence of coronary heart disease rate; prevent and treat alzheimer's disease and cancer; strengthen the body's immunity.

2. Resveratrol products mainly include three types, including synthetic, fermented and plant extracts. Each type has a corresponding application industry. Application areas include dietary supplements, cosmetics, food and beverages, and downstream application industries will require more resveratrol. Therefore, resveratrol has huge market potential in the future. The manufacturing industry is trying to produce resveratrol with good performance through improved technology.

Purchase raw material vegetation (bark) Crushing workshop Powder raw material feeding Full Dissolving the target product with lytic enzyme Filtrating and separating Refining and purifying Drying Packing of the finished product

1) For the reason that the soaking process involved, the amount of solvent in the production process is huge, and the workshop is equipped with an ethanol distillation recycling tower;

2) Six 6500-liter stainless steel refiner reactors, four 6500-liter enamel reactors;

3) Two 30-meter fully automatic countercurrent dissolution production lines;

4) As there is huge amount of steam involved in the distillation and a large amount of solvent recycling, the factory uses the steam uniformly distributed from the industrial park (normal steam pressure is 8 kg, which is 8 atmospheres), and the factory owned boiler is used in a small amount;

the origin of medicinal materials for the low purchase price

For the extraction of berberine, the factory owns 5,000 square meters infiltrating warehouses with the capacity to soak 80 tons of raw material one-time. When the raw materials are soaked until the bark is white (when the target product of berberine is fully dissolved in a solvent, usually ethanol, the original bark turning white means sufficient soaked), the soak liquid is concentrated, refined and purified, and dried (it can be delivered in the form of powder or not in the form of powder, up to the buyer’s request) to obtain the finished berberine.

The content difference between titrametric method and HPLC inspection is small. The content of palmatine and jatrorrhizine meets the standards of the Chinese Pharmacopoeia 2015, and the heavy metals meet the standard for export.

1Stable Supply:Stable supply throughout the year, product delivery on time, full refund for delayed delivery.

2Quality Assurance:The platform transaction will follow up throughout the procedure, and the quality is controlled. If the quality is inconsistent or defective, we will refund you in full amount.

3Safety of Trade:The platform guarantees full payment and guarantees transaction security.

After submitting, we will contact you ASAP. E-mail:service@lookchem.com

Success!