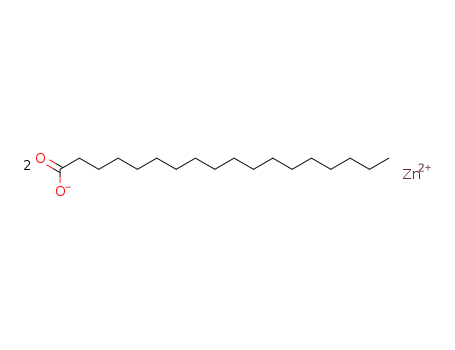

- Chemical Name:ZINC stearate

- CAS No.:557-05-1

- Deprecated CAS:72535-55-8,8028-87-3,256482-37-8

- Molecular Formula:C36H70O4Zn

- Molecular Weight:632.339

- Hs Code.:29157090

- European Community (EC) Number:209-151-9,257-363-5

- ICSC Number:0987

- UN Number:3077

- UNII:H92E6QA4FV

- DSSTox Substance ID:DTXSID7027209

- Nikkaji Number:J136.463D

- Wikipedia:Zinc_stearate

- Wikidata:Q204923

- NCI Thesaurus Code:C84251

- RXCUI:1310553

- Mol file:557-05-1.mol

Synonyms:aluminum monostearate;aluminum tristearate;ammonium stearate;calcium stearate;magnesium stearate;octadecanoic acid;sodium stearate;stearic acid;zinc stearate

Xi

Xi