- Cellulose

- Cellulose acetate

- Cellulose acetate phthalate

- Cellulose diacetate

- CELLULOSE GLYCOLIC ACID SODIUM SALT

- Cellulose microcrystalline

- Cellulose,ethers,carboxymethyl ether,calcium salt

- 9004-36-852440-02-5

- 9004-38-0Cellulose acetate phthalate

- 9004-41-5CYANOETHYL CELLULOSE

- 90045-23-1Garcinia cambogia, ext.

- 90045-28-6Gaultheria procumbens,ext.

- 90045-36-6Ginkgo biloba

- 90045-38-8Ginseng, Panaxquinquefolium, ext.

- 9004-53-9Dextrin

- 9004-54-0Dextran

- 90045-43-5Grapefruit, ext.

Hot Products

- 25988-97-0Poly(2-hydroxypropyldimethylammonium chloride)

- 90274-24-1Benzenemethanol, 4-hydroxy-alpha-(((3-(4-hydroxyphenyl)-1-methylpropyl)amino)methyl)-, hydrochloride

- 3234-85-3Tetradecanoic acid,tetradecyl ester

- 764667-64-31,3-Dioxane-4,6-dione,5-[1-hydroxy-2-(2,4,5-trifluorophenyl)ethylidene]-2,2-dimethyl-

- 26896-18-4Isononanoic acid

- 756-13-8Perfluoro(2-methyl-3-pentanone)

- 460-73-11,1,1,3,3-Pentafluoropropane

- 68920-66-1Alcohols, C16-18 and C18-unsatd, ethoxylated

- 104987-11-3Tacrolimus

- 141-53-7Sodium formate

- 8001-54-5Quaternary ammonium compounds, alkylbenzyldimethyl, chlorides

- 9003-39-8Povidone

- 10161-34-9Trenbolone acetate

- 402957-28-2Telaprevir

- 68-19-9Cyanocobalamin

|

Basic Information |

|

Post buying leads |

|

Suppliers |

| Name |

Cellulose acetate |

EINECS | N/A | ||

| CAS No. | 9004-35-7 | Density | 1.3g/mLat25°C(lit.) | ||

| PSA | 63.22000 | LogP | -0.09540 | ||

| Solubility |

Stability

Toxicology

Toxicity data |

Melting Point |

230-300℃ |

||

| Formula | [C6H7O2(OH)3-m(OOCCH3)m],m=0~3 | Boiling Point | 210 °C | ||

| Molecular Weight | 0 | Flash Point | 304 C (closed cup) | ||

| Transport Information | N/A | Appearance | white powder | ||

| Safety |

|

Risk Codes | N/A | ||

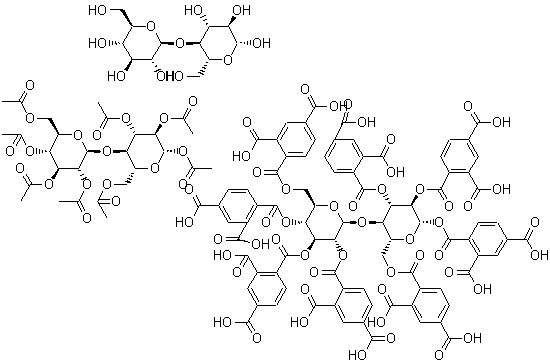

| Molecular Structure |

|

Hazard Symbols | N/A | ||

| Synonyms |

a432-130b;acetatecotton;acetateesterofcellulose;aceticacid,celluloseester;acetose;acetyl35;allogel;ampacetc/a |

Cellulose acetate Chemical Properties

density: 1.3 g/mL at 25 °C

refractive index: n20/D 1.475

Other names: cellulose acetate sac 20; cellulose acetate dac 20; Cellulose Mono Acetate; Cellulose Monoacetate;

Cellulose acetate(9004-35-7) is the acetate ester of cellulose.

Cellulose acetate(9004-35-7) is moldable, in contrast to cellulose nitrate, which is not. It, however, has poor resistance to moisture. To overcome this disadvantage, treating the cotton linters with a mixture of butyric acid, acetic acid, and acetic anhydride produces a mixed acetate-butyrate.

The Structure of Cellulose acetate(9004-35-7):

Cellulose acetate History

Cellulose acetate Uses

Cellulose acetate(9004-35-7) is used as a film base in photography, and as a component in some adhesives.

Cellulose acetate(9004-35-7) is also used as a synthetic fiber.

Cellulose acetate Production

There are several production methods for Cellulose acetate(9004-35-7):

1. Purified cellulose from wood pulp or cotton linters

2. Mixed with glacial acetic acid, acetic anhydride, and a catalyst

3. Aged 20 hours- partial hydrolysis occurs

4. Precipitated as acid-resin flakes

5. Flakes dissolved in acetone

6. Solution is filtered

7. Spinning solution extruded in column of warm air. Solvent recovered

8. Filaments are stretched and wound onto beams, cones, or bobbins ready for use