10.1021/jacs.7b02775

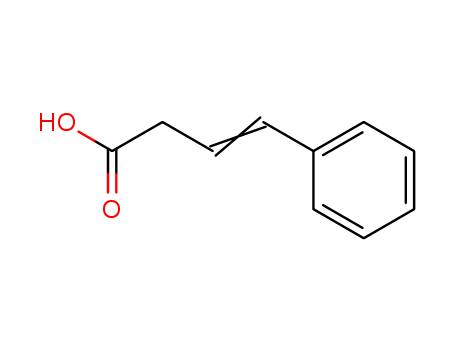

The study presents a novel catalytic method for the carboxylation of allylic C(sp3)–H bonds in terminal alkenes using CO2. The researchers employed a cobalt/Xantphos complex in conjunction with AlMe3 to achieve this transformation. The Co(acac)2/Xantphos/AlMe3 system was found to be highly effective, enabling the conversion of a wide range of allylarenes and 1,4-dienes into linear styrylacetic acid and hexa-3,5-dienoic acid derivatives with excellent regioselectivity and functional group tolerance. The study highlights the significant role of Xantphos as a hemilabile ligand, facilitating the generation of a low-valent allylcobalt species that reacts with CO2 to form the desired carboxylated products. The developed method not only offers a straightforward route for the synthesis of ?-butyrolactones but also demonstrates potential for further synthetic applications in organic chemistry.