10.1002/anie.201702727

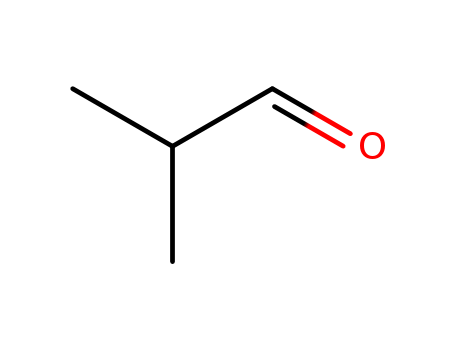

The research presents an unexpected direct method for synthesizing industrially significant N-vinyl amides from aldehydes and esters using vinyl azide–enolate [3+2] cycloaddition. The study initially explored alkylation reactions of an ester with alkyl iodides to access quaternary esters but fortuitously discovered the formation of N-vinyl amides when using a two-carbon-atom iodo azide. This led to a comprehensive investigation of the reactivity of various esters and aldehydes with iodo azide 14. The reaction likely proceeds through an initial [3+2] cycloaddition involving a vinyl azide generated in situ, followed by rearrangement and nitrogen extrusion. Aldehydes such as aldehyde 27, isobutyraldehyde 29, aldehydes 30 and 32. The research employed quantum computational analysis to support the proposed mechanism and to estimate the activation energies for the cycloaddition with different azides. The study provides new insights into atom-efficient amide synthesis and suggests a potential reevaluation of azidoethene as a synthetic reagent, with implications for drug formulation, tissue engineering, and the development of poly(vinyl amide) polymers.

10.1016/j.tetlet.2009.09.061

This research aimed to develop an efficient catalytic system for the aerobic epoxidation of olefins using l-oxo-bisiron(III) porphyrins [(FeIIITPP)2O] as catalysts, isobutylaldehyde as co-reductants, and dioxygen as the oxidant. The study demonstrated a significant enhancement in reactivity compared to mono-metalloporphyrin catalysts, achieving a turnover number (TON) of up to 1400 million for the catalyst. The researchers proposed a plausible mechanism involving both binuclear and mononuclear intermediates and confirmed the formation of high-valent iron intermediates through in situ UV–vis spectroscopy. The results showed that the catalytic system was highly active and selective under ambient conditions, with excellent performance across various substrates, making it a promising approach for the production of epoxides in an economical and environmentally friendly manner.

F,

F, Xn

Xn

F:Flammable;

F:Flammable;