RSC Advances p. 45965 - 45973 (2015)

Update date:2022-08-30

Topics:

Srilakshmi, Chilukoti

Srilakshmi, Chilukoti

Rao, G. Mohan

Rao, G. Mohan

Saraf, Rohit

Saraf, Rohit

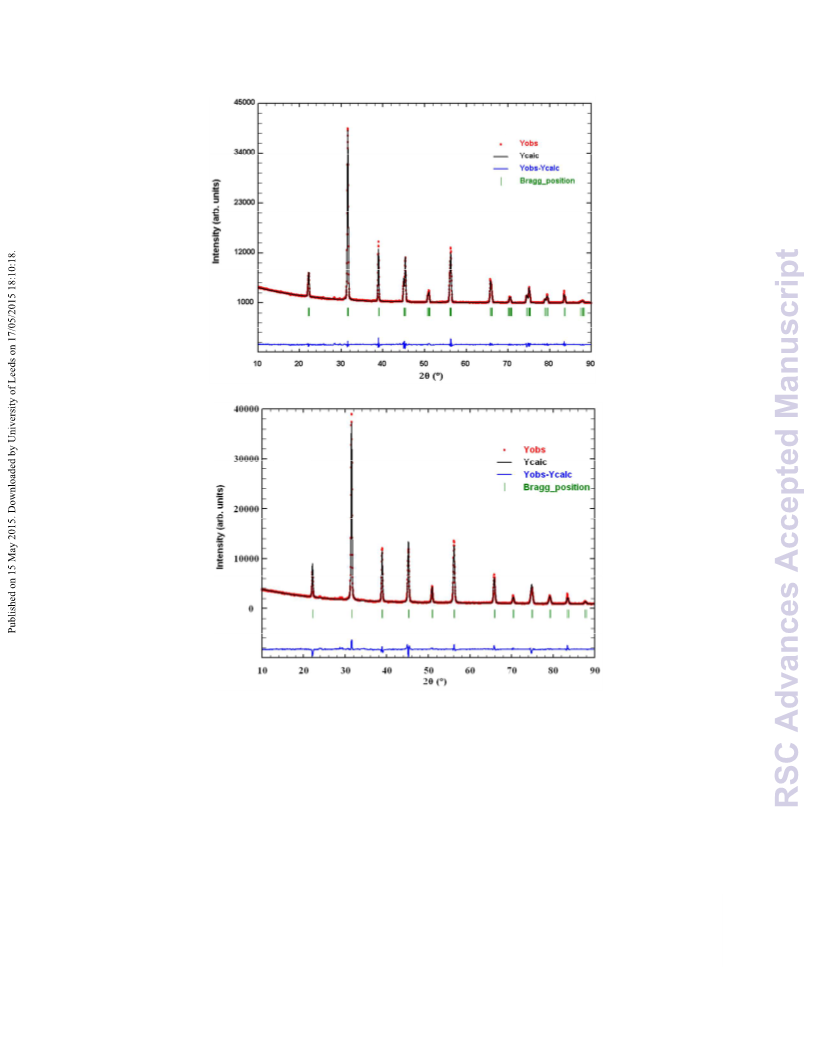

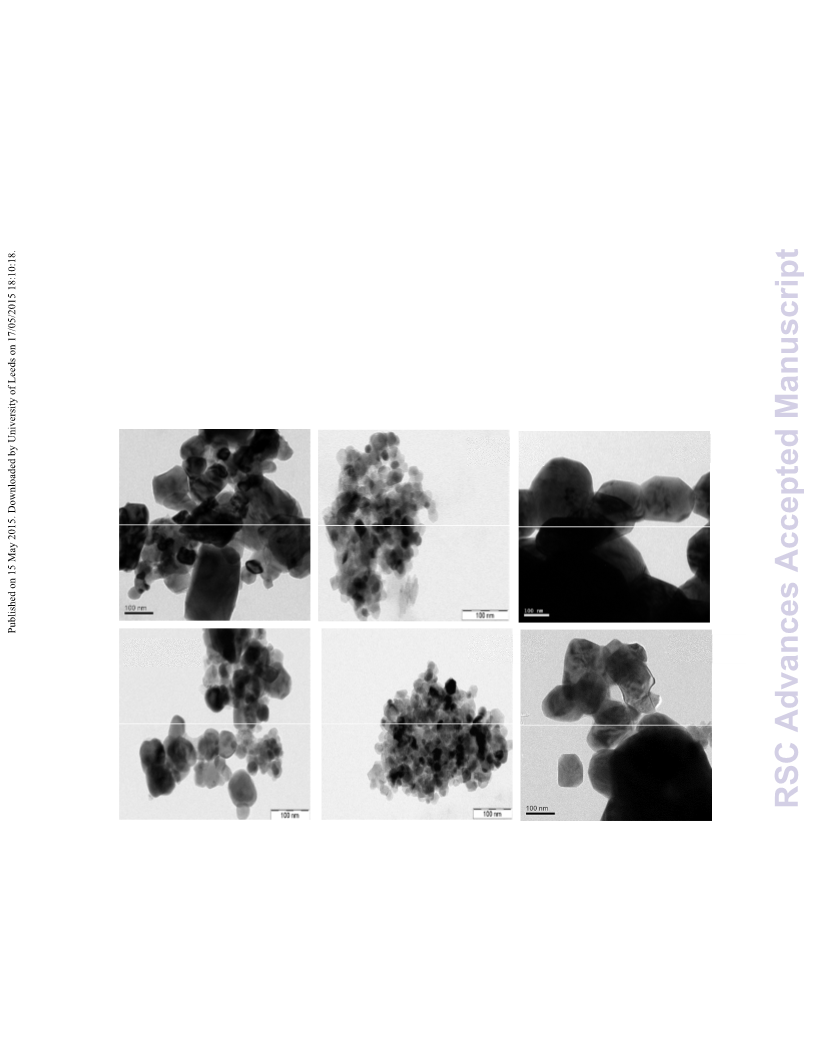

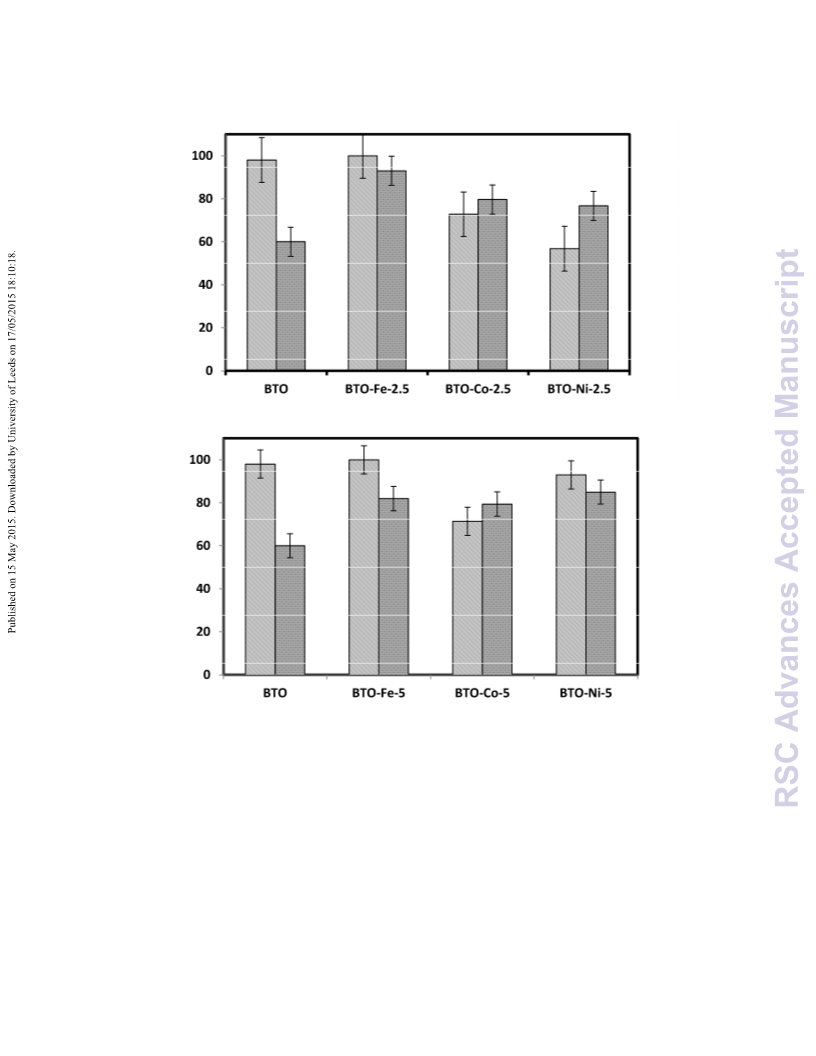

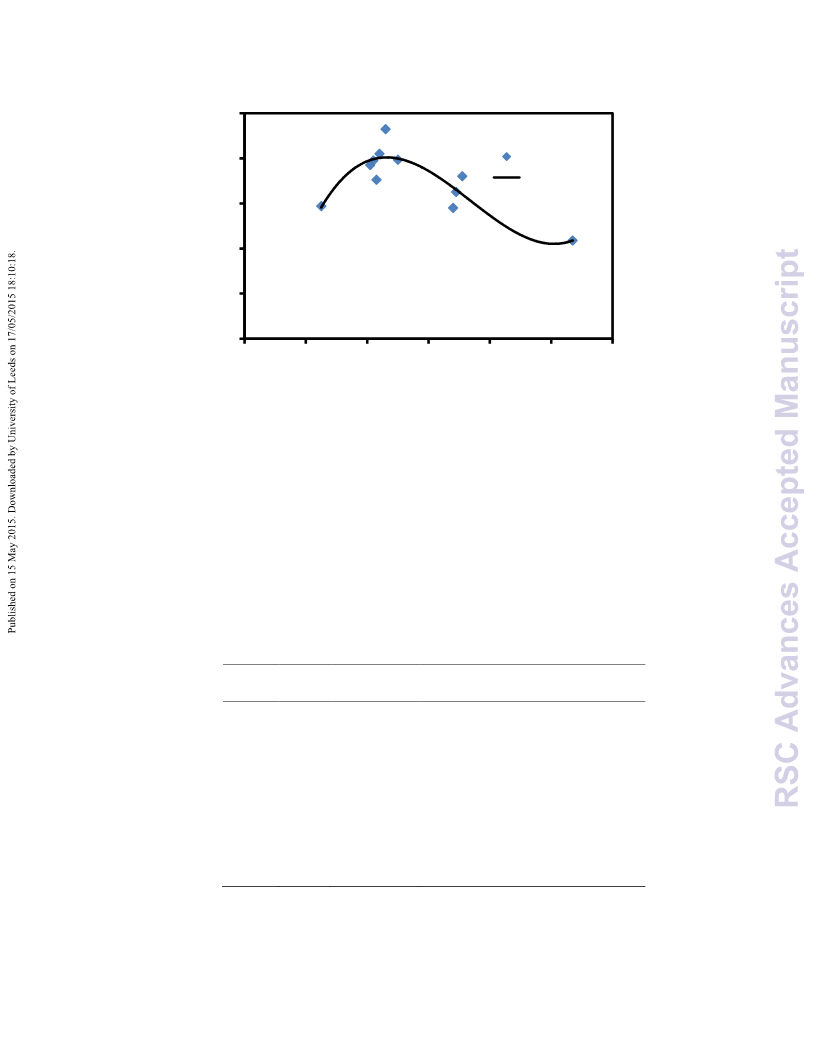

In the present study, we have synthesized Fe, Co and Ni doped BaTiO3 catalyst by a wet chemical synthesis method using oxalic acid as a chelating agent. The concentration of the metal dopant varies from 0 to 5 mol% in the catalysts. The physical and chemical properties of doped BaTiO3 catalysts were studied using various analytical methods such as X-ray diffraction (XRD), Fourier transform infrared spectroscopy (FT-IR), BET surface area and Transmission electron microscopy (TEM). The acidic strength of the catalysts was measured using a n-butylamine potentiometric titration method. The bulk BaTiO3 catalyst exhibits a tetragonal phase with the P4mm space group. A structural transition from tetrahedral to cubic phase was observed for Fe, Co and Ni doped BaTiO3 catalysts with an increase in doped metal concentration from 1 to 5 mol%. The particle sizes of the catalysts were calculated from TEM images and are in the range of 30-80 nm. All the catalysts were tested for the catalytic reduction of nitrobenzene to azoxybenzene. The BaTiO3 catalyst was found to be highly active and less selective compared to the doped catalysts which are active and highly selective towards azoxybenzene. The increase in selectivity towards azoxybenzene is due to an increase in acidic strength and reduction ability of the doped metal. It was also observed that the nature of the metal dopant and their content at the B-site has an impact on the catalytic reduction of nitrobenzene. The Co doped BaTiO3 catalyst showed better activity with only 0.5 mol% doping than Fe and Ni doped BaTiO3 catalysts with maximum nitrobenzene conversion of 91% with 78% selectivity to azoxybenzene. An optimum Fe loading of 2.5 mol% in BaTiO3 is required to achieve 100% conversion with 93% selectivity whereas Ni with 5 mol% showed a conversion of 93% and a azoxybenzene selectivity of 84%. This journal is

View More

Contact:Tel: +86-25-58353800

Address:23 Lijing Road, Nanjing Hi-Tech Zone, Nanjing, Jiangsu, China, 210061

Chongqing Changfeng Chemical Co., Ltd.

website:http://www.changfengchem.com

Contact:+86-23-67896333

Address:30th Floor, Longhu Ziduxingzuo Building A, 1st Branch,YuSong Rd., Yubei District, Chongqing, China

Chengdu Cogon Bio-tech Co., Ltd.

Contact:86-28-85171192

Address:NO.52.YongFeng Rd. Chengdu,610041,P.R.China.

Shanghai Mio Chemical Co., Ltd

Contact:0086 21- 64401188-622

Address:16 Floor NO.2 Jiefang Building, No. 4855 Dushi Road, 201100 Shanghai, P.R.China

SHANGHAI T&W PHARMACEUTICAL CO., LTD.

website:http://www.trustwe.com

Contact:+86-21-61551611

Address:601, No. 1, 2277 Nong, Zu Chongzhi Road, Zhangjiang Hightech. Park, Pudong

Doi:10.1016/j.jphotochem.2015.04.015

(2015)Doi:10.1016/S0040-4039(00)75247-6

(1975)Doi:10.1016/j.tetasy.2007.05.025

(2007)Doi:10.1134/S0965544119120119

(2019)Doi:10.1055/s-0034-1379934

(2015)Doi:10.1134/S0036023606080043

(2006)