114798-26-4 Usage

Originator

Alsartan, Aristo Pharmaceutical Ltd., India

Uses

Different sources of media describe the Uses of 114798-26-4 differently. You can refer to the following data:

1. Losartan is a nonpeptide angiotensin II AT1-receptor antagonist. Antihypertensive.

2. antihypertensive;antagonist of angiotensin type 1

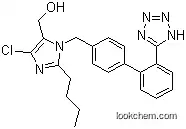

Definition

ChEBI: A biphenylyltetrazole where a 1,1'-biphenyl group is attached at the 5-position and has an additional trisubstituted imidazol-1-ylmethyl group at the 4'-position

Manufacturing Process

2-Butyl-4-chloro-1-(2'-(tetrazol-5-yl)biphenyl-4-ylmethyl)-1H-imidazole-5- methanolpotassium was synthesized in 5 stages. 1. Methyl 4'-methylbiphenyl-2-carboxylate (44.2 mmol), 0.5 N KOH in methanol (133 mmol), and water (50 mL) were mixed and refluxed under nitrogen. After 5 hours, the solvent was removed in vacuo and water (200 mL) and ethyl acetate (200 mL) added. The aqueous layer was acidified with concentrated hydrochloric acid to a pH of 3 and the layers were separated. The aqueous phase was extracted with ethyl acetate, the organic layers collected, dried (MgSO4) and the solvent removed in vacuo to yield 8.71 g of a 4'-methylbiphenyl-2-carboxylic acid, melting point 140.0-145.0°C. 2. 4'-Methylbiphenyl-2-carboxylic acid (41 mmol) and thionyl chloride (411 mmol) were mixed and refluxed for 2 hours. The excess thionyl chloride was removed in vacuo and the residue was taken up in toluene. The toluene was removed by rotary evaporation. The crude acid chloride was then added slowly to cold (0°C) concentrated NH4OH (50 mL) so that the temperature was kept below 15°C. After 15 minutes of stirring, water (100 mL) was added and solids precipitated. These were collected, washed with water and dried under high vacuum over P2O5 to yield 7.45 g of a white solid, melting point 126.0-128.5°C. The above product amide (35 mmol) and thionyl chloride (353 mmol) were mixed and refluxed for 3 hours. The thionyl chloride was removed using the same procedure as described above. The residue was washed with a little hexane to yield 6.64 g of 4'-methyl-2-cyanobiphenyl, melting point 44.0- 47.0°C. 3. 4'-Methyl-2-cyanobiphenyl (5.59 g) was brominated using benzoyl peroxide as an initiator. The product was recrystallized from ether to yield 4.7 g of 4'- bromomethyl-2-cyanobiphenyl, melting point 114.5-120.0°C.4. 4'-Bromomethyl-2-cyanobiphenyl (4.6 g) was alkylated onto 2-n-butyl-4-

chloro-5-(hydroxymethyl)-imidazole. For separation of the product was used a

flash chromatography in 1:1 hexane/ethyl acetate over silica gel. The

regioisomeric products yielded 2.53 g of the faster eluting isomer.

Recrystallization from acetonitrile yielded 1.57 g of analytically pure 2-n-butyl4-chloro-1-[2'-cyanobiphenyl-4-yl)methyl]-5-(hydroxymethyl)-imidazole,

melting point 153.5 -155.5°C.

5. 2-n-Butyl-4-chloro-1-[(2'-cyanobiphenyl-4-yl)-methyl]-5-(hydroxymethyl)-

imidazole (10 mmole), sodium azide (10 mmol), and ammonium chloride (30

mmol) were mixed in DMF (150 mL) under N2 at 100°C for 2 days, after

which the temperature was raised to 120°C for 6 days. The reaction was

cooled and 3 more equivalents each of ammonium chloride and sodium azide

were added. The reaction was again heated for 5 days at 120°C. The reaction

was cooled, the inorganic salts filtered, and the filtrate solvent removed in

vacuo. Water (200 mL) and ethyl acetate (200 mL) were added to the residue

and the layers were separated. The aqueous layer was extracted with ethyl

acetate, the organic layers were collected, dried (MgSO4) and the solvent

removed in vacuo, to yield a dark yellow oil. The product was purified by flash

chromatography in 100% ethyl acetate to 100% ethanol over silica gel to

yield 5.60 g of a light yellow 2-n-butyl-4-chloro-5-hydroxymethyl-1-[(2'-(1Htetrazol-5-yl)biphenyl-4-yl)methyl]imidazole. Recrystallization from acetonitrile

yielded 4.36 g of light yellow crystals which still melted broadly. The crystals

were taken up in 100 mL of hot acetonitrile. The solid that did not dissolve

was filtered off to yield 1.04 g of product as a light yellow solid, melting point

of 2-n-butyl-4-chloro-5-hydroxymethyl-1-[(2'-(1H-tetrazol-5-yl)biphenyl-4-

yl)methyl]imidazole 183.5-184.5°C.

2-n-Butyl-4-chloro-5-hydroxymethyl-1-[(2'-(1H-tetrazol-5-yl)biphenyl-4-

yl)methyl]imidazole may be converted to potassium salt.

Brand name

Cozaar (Merck).

Therapeutic Function

Antihypertensive

General Description

Losartan, 2-butyl-4-chloro-1-[p-(o-1H-tetrazol-5-yl-phenyl)benzyl]imidazole-5-methanol monopotassiumsalt (Cozarr), was the first nonpeptide imidazole to beintroduced as an orally active angiotensin II antagonist withhigh specificity for AT1. When administered to patients, itundergoes extensive first-pass metabolism, with the 5-methanol being oxidized to a carboxylic acid. This metabolismis mediated by CYP 2C9 and 3A4 isozymes. The 5-methanol metabolite is approximately 15 times more potentthan the parent hydroxyl compound. Because the parent hydroxylcompound has affinity for the AT1 receptor, strictlyspeaking, it is not a prodrug.

Flammability and Explosibility

Nonflammable

Check Digit Verification of cas no

The CAS Registry Mumber 114798-26-4 includes 9 digits separated into 3 groups by hyphens. The first part of the number,starting from the left, has 6 digits, 1,1,4,7,9 and 8 respectively; the second part has 2 digits, 2 and 6 respectively.

Calculate Digit Verification of CAS Registry Number 114798-26:

(8*1)+(7*1)+(6*4)+(5*7)+(4*9)+(3*8)+(2*2)+(1*6)=144

144 % 10 = 4

So 114798-26-4 is a valid CAS Registry Number.

InChI:InChI=1/C22H23ClN6O/c1-2-3-9-20-24-21(23)19(14-30)29(20)13-15-10-11-17(16-7-5-4-6-8-16)18(12-15)22-25-27-28-26-22/h4-8,10-12,30H,2-3,9,13-14H2,1H3,(H,25,26,27,28)

114798-26-4Relevant articles and documents

Novel and efficient debenzylation of N-benzyltetrazole derivatives with the rosenmund catalyst

Seki, Masahiko

, p. 3249 - 3255 (2014)

The Rosenmund catalyst (Pd/BaSO4) was found to efficiently catalyze debenzylation of N-benzyltetrazole derivatives with ammonium formate by catalytic transfer hydrogenation under mild conditions. The protocol has been applied to functionalized substrates to provide various angiotensin II receptor blockers in excellent yields.

Unusual detritylation of tritylated tetrazole in Sartan molecules

Srimurugan, Sankareswaran,Suresh, Paulsamy,Babu, Balaji,Hiriyanna, Salmara Ganeshbhat,Pati, Hari Narayan

, p. 383 - 384 (2008)

Tritylated tetrazole of 2a underwent unusual detritylation under basic reaction condition during the synthesis of methyl ether of olmesartan medoxomil 1. The unusual detritylation was found to be a common feature in the case of all tetrazole containing Sartan molecules (3-7).

Method for preparing high-purity losartan

-

Paragraph 0020-0034, (2020/10/19)

The invention relates to a method for preparing high-purity losartan. The method comprises steps as follows: (1), a losartan crude product is added to an organic solvent or a mixed solvent of an organic solvent and water, and the mixture is heated to reach 20-80 DEG C and stirred; (2), the system is cooled directly or cooled after water is added or cooled to 0-5 DEG C after a part of solvent is evaporated, a material is precipitated, filtered and dried, and losartan is obtained, wherein the organic solvent used in the step (1) is any one of tetrahydrofuran, butanone, acetone and methyl alcohol or is a mixed solvent of any one of the four solvents and water. The losartan obtained with the method has high purity, any individual impurity can be reduced to 0.2% or even under 0.1%, the purity of the losartan can reach 99.5%, the cost of the method is lower, the refining yield is high, and the method is very simple in operation, environment-friendly and suitable for industrial production.

Nickel-Catalyzed Denitrogenative ortho-Arylation of Benzotriazinones with Organic Boronic Acids: an Efficient Route to Losartan and Irbesartan Drug Molecules

Thorat, Vijaykumar H.,Upadhyay, Nitinkumar Satyadev,Cheng, Chien-Hong

, p. 4784 - 4789 (2018/11/10)

Denitrogenative ortho-arylation, vinylation and methylation of 1,2,3-benzotriazin-4-(3H)-ones with organic boronic acids catalyzed by nickel complexes to give a wide range of o-substituted benzamides were demonstrated. Further, the catalytic reaction is successfully applied to the synthesis of the popular hypertensive drugs losartan and irbesartan in high yields. (Figure presented.).